Composite decking is a popular alternative to traditional wood, offering durability, low maintenance, and an eco-friendly option for outdoor spaces. But what exactly is composite decking made of? This article will break down the materials and processes involved in creating composite boards, ensuring you have all the information you need to make an informed decision.

Key Ingredients in Composite Decking

Primarily consists of a blend of wood fibers and plastic. These materials are often sourced from recycled content, making composite decking an environmentally responsible choice. The wood fibers provide a natural look and feel, while the plastic enhances strength and longevity.

Wood Fibers

Reclaimed sawdust, wood chips, and other wood by-products make up the wood flour that gives the decking its natural appearance and texture.

Plastics

Manufacturers typically use polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC) to add durability to the decking.

- Polyethylene (PE): This plastic is lightweight, durable, and commonly used in composite decking.

- Polypropylene (PP): With a higher melting point and better resistance to heat and chemicals, PP is ideal for decks in hot climates.

- Polyvinyl Chloride (PVC): Though less common in traditional composite decking, PVC offers enhanced moisture and rot resistance.

Additives

Various additives improve the decking’s performance and appearance:

- UV Stabilizers: These protect the decking from sun damage and fading.

- Pigments: They ensure consistent color throughout the board.

- Stabilizers and Bonding Agents: These enhance strength and durability.

The Manufacturing Process

Produced using two main processes: extrusion and compression molding.

Extrusion

In this process, the mixed materials (wood fibers, plastic, and additives) are heated until malleable. The mixture is then forced through a mold that shapes the decking boards.

Compression Molding

Here, raw materials are placed into a mold, and pressure shapes the boards. This method often results in a more consistent texture and density.

Both processes ensure that the decking remains strong, durable, and resistant to common issues like warping, rotting, and insect damage.

Capped vs. Uncapped Composite Decking

When choosing composite decking, you’ll primarily find capped options. Capped decking includes a protective outer layer that surrounds the board, offering enhanced protection against the elements.

Capped

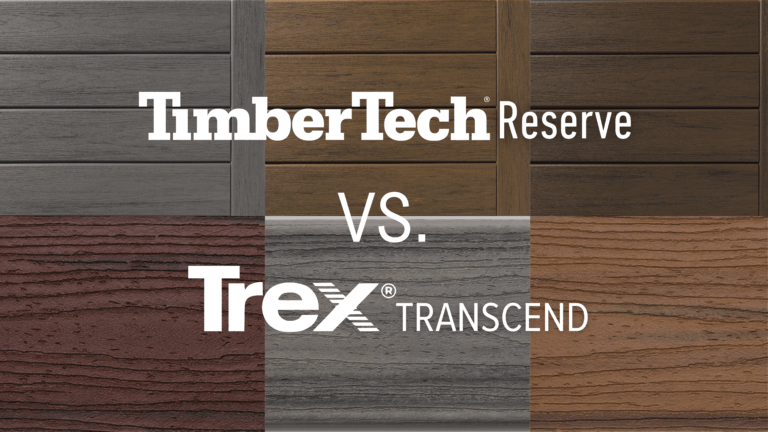

The protective cap shields the board from moisture, stains, fading, and scratches. This protection keeps the deck looking new for longer, even with minimal maintenance. Leading brands like Trex, TimberTech, and Fiberon offer capped composite options known for their durability.

Uncapped

This older technology lacks a protective cap, making it more vulnerable to damage from moisture, UV rays, and daily wear and tear. Without the cap, uncapped decking may require more frequent maintenance and show signs of wear sooner. Due to these limitations, most homeowners now prefer the enhanced durability of capped composite decking.

Advantages of Composite Decking

Offers several advantages over traditional wood:

Low Maintenance

You won’t need to stain, seal, or paint it. A quick clean with soap and water is usually all it takes to maintain its appearance.

Durability

Resists warping, splintering, and insect damage, making it a long-lasting option for outdoor spaces.

Enhanced Protection

The protective cap on capped decking shields it from moisture and UV rays, ensuring a longer lifespan.

Eco-Friendly

Made from recycled materials, supports sustainable living while delivering high performance.

Conclusion

So, what is composite decking made of? It’s a blend of wood fibers and plastic, enhanced with protective additives, and manufactured into durable, low-maintenance boards. Capped composite decking, offered by leading brands like Trex, TimberTech, and Fiberon, provides superior durability and protection, making it the ideal choice for long-lasting, beautiful outdoor spaces.